Laser Scanning

John Moore has recently made a significant investment in state of the art laser scanning equipment and editing software. In fact, the company now offers a number of different design services, so that many of the parts we produce can be altered and modified to suit the exact, unique needs of individual customers - customer feedback, advice and recommendations are always welcome.

Site-scanning Service

The company's site-scanning service therefore now allows customers to temporarily remove parts from an item of plant, during a period of downtime, so that after the scanning and meshing process has been completed, the parts can be replaced to allow the plant to go back to work.

Use of this equipment effectively means that John Moore can now scan and copy difficult-to-obtain castings and other parts, directly from original, existing items. The scanning process is exceptionally accurate, and can be carried out at our offices or on-site, depending on the needs and convenience of the individual customer.

Data Usage and 3D Editing

Once the scanning process has been completed and a finished mesh (complete 3D image) of the part has been obtained, the part can be edited and altered on screen in order to implement any relevant changes, which could be designed to increase wear and overall part life, improve function or even alter weight or hardness of materials.

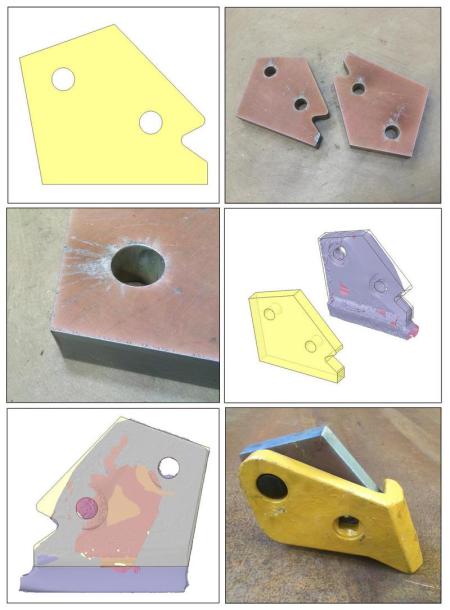

Please view some of the images below, to see some examples of how we have interpreted individual customer requirements in the past, in order to provide alternative solutions to many different plant and machinery issues and enquiries.

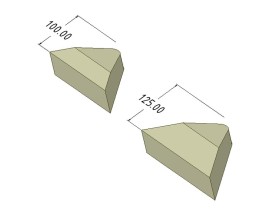

Case Studies - Cactus Grab Tip

The image to the left shows a pair of grab tips for a cactus grab machine attachment. When John Moore received the original tip it's overall height measured only 100mm. On this occasion, through manipulating and pulling the bottom edge of the tip John Moore were able offer the customer an alternative wear part, measuring 125mm overall height, therefore increase wear and generally tip life. In our experience most wear parts have an area, edge or face that can be successfully manipulated or adjusted, to either increase generally wear, or even help to improve functionality of the plant being operated.