Measurement/Identification of Reversible Edges

John Moore is an established cutting edge manufacturer, having operated within the industry for many years. As such, the company has been able to gradually

build a substantial database of information, regarding different cutting edge sets or groups, that are naturally common to certain buckets/machines etc.

of information, regarding different cutting edge sets or groups, that are naturally common to certain buckets/machines etc.

The shear size of our database ,

and the number of cutting edges the company has manufactured over the years, means that we are usually confident that if a customer can give us certain key pieces of information, we can check

certain measurements against our database and identify the cutting edge set/group that the customer requires. At which point, we can usually offer a quotation for the replacement cutting

edge.

,

and the number of cutting edges the company has manufactured over the years, means that we are usually confident that if a customer can give us certain key pieces of information, we can check

certain measurements against our database and identify the cutting edge set/group that the customer requires. At which point, we can usually offer a quotation for the replacement cutting

edge.

In order for us to cross-reference and identfy, remotely, the cutting edges that a customer requires ready for pricing, we need the follow pieces of information:

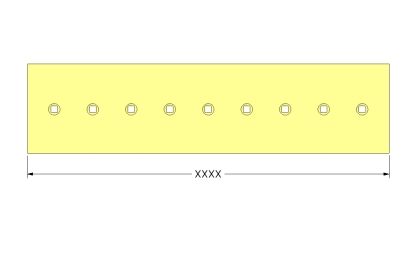

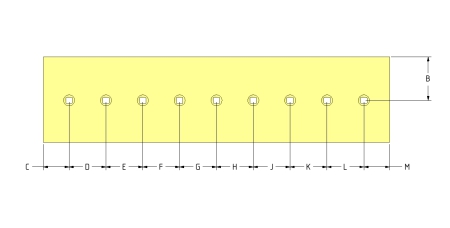

Length

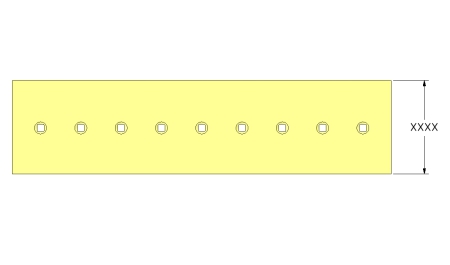

Width

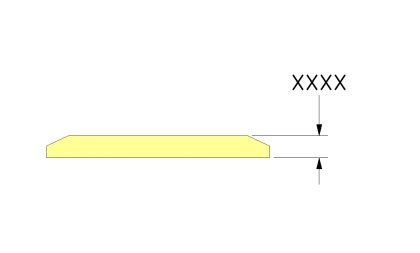

Thickness

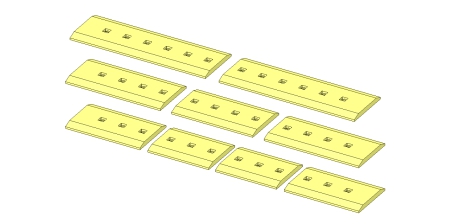

Number of Sections

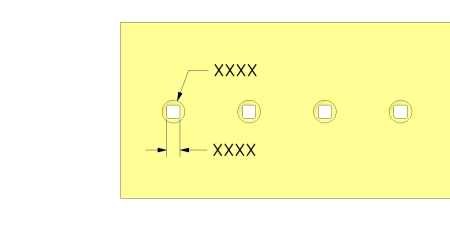

Hole Centres / Spacing

Hole Size

Photographic Detail

We always welcome information and data, taken by customers themselves. However, if you are in need of a cutting edge and are unsure regarding the measurements you have taken, then please feel free to send us photographic details.

You can do this by laying a measuring tape inside the bucket, next to the existing bolts (millimetres side closest to the bolts), and by then taking a photo directly over the tape, at each bolt position, therefore allowing us to see where the tape measures up to each hole. When doing this please include a photo of the tape at the start of the bucket/edge, and at the end of the bucket/edge to confirm it's overall length.

As with any written information or diagrams we receive, if we believe the measurements from any photos match up to a cutting edge set/group we already have on the system, we will be able to provide an accurate quotation for the new cutting edge.